We help Low & Mid-Rise developers

fast—track their structures with precision building systems

Working With You

Collaboration

We discuss your objectives, project details, and guide you to accelerate your build cycle with systemized engineering and structural kits.

Engineering contract

Is established with clearly defined deliverables, payment schedule, including structural calculations, engineering stamps and approvals.

Fabrication & Install

We fabricate to agreed standards, with production inspections and quality verification, before deploying our professional assembly team at your project site.

Seismic Heavy Timber

Structures

Structure Engineering

Rebar Kits

Assembly

Especially when fabrication is performed on site, with varying levels of quality?

Our assembly kits are distinct completion events, and not a floating project schedule.

These habits and strategies are hard to change. But we can help!

Change Orders

Change orders are costly to the customer and encourage slipping delivery dates, and increase your risk.

Empower your customer’s to visualize the structure, so change orders are eliminated at manufacturing start.

Floating Project Schedule

Your job site is a mini factory. Power tools are utilized, and pose a safety risk. Traditional projects have floating schedule, as the completion dates are expected to change. Does your project require dedicated Project managers to keep up with changes?

Crew Dependency

Competition for available crews is a constant challenge. And your product quality is dependent on retaining skilled crew members.

Precision joinery is less dependent on skilled workers at your construction site..

slow your project completion or limit the capabilities you offer to clients!

Grid Concrete Process

Grid fabrication process ensures quality and speed in every project

Excavation

- Systemized site preparation

- Shaping

- Compaction

Pad Preparation

- 2 day cycle

- Precision compaction

Precision concrete forming

- Concrete Forms placed in 2 days

- Predictable precision to 2mm accuracy

Steel Mesh Install

- Steel installed and tied in 1-2 days

- Stronger welded steel

Precision Timber Manufacturing

QUALITY

SAVINGS

INVESTMENT

6 month completion

Structures for Exclusive Estate Builders

Fast track your projects

Our Service

structures for exclusive clients

Momentum

- 1 day framing cycle

- 2 week foundation build

- 4 hour rebar placing

- Repeatable, predictable quality

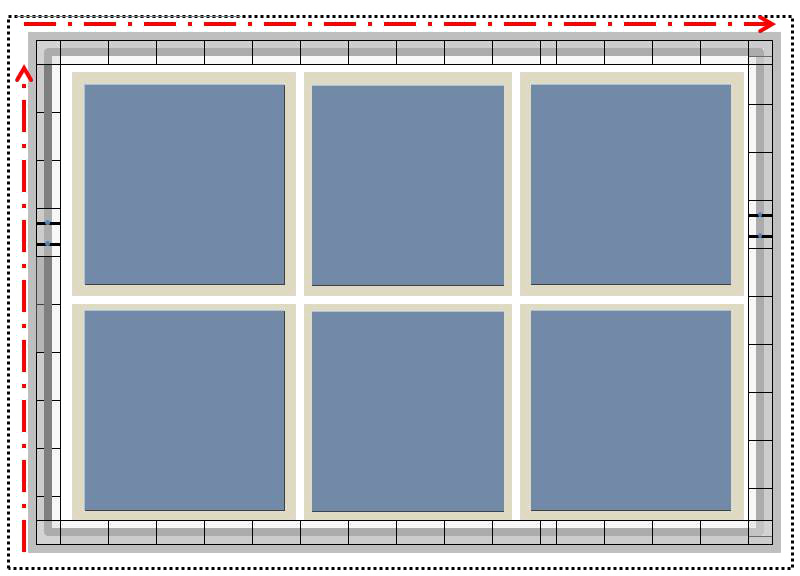

Grid Concrete System

- Modular foundation components

- Rebar pre-welded for quick assembly

- Concrete forms establish geometry precision

- Your client’s benefit from lower pier and beam insurance rates

Joinery Frame Kit

- High quality timber

- Timbers milled to millimeter accuracy

- Assembled with rubber mallets

- Eliminate all nailing in structure

- No skilled framing carpenters required

- Peace of mind for you and your customers

Engineered Plans

- From your designed CAD floor plan

- Systemized engineering

- Creates a milling and steel plan

Assembly Sequence

Foundation

- Form Schematic completed

- Foundation profile for sills

- Soil Test completed

- Additional Piers engineered

- Foundation poured and dried

Flooring

- Sub-floor Cut/Attached

- Sheet Rock attached and taped

- Paint of walls and trim

- Plywood and wood floors completed for all spaces

Framing of Structure

- Bolting and joining Sills & Cross Beams

- Plywood Drilled and anchored

- Roof trusses anchored and drilled

- Insulation of outside walls completed

- Windows installed and anchored

Finishing

- Cabinetry

- Bathrooms

- Sewage connected

- Electrical activated

- Water test

Services

- Electrical installed

- Plumbing all connections-leak test

- Completed and inspected as a single work package

Move In

- Final Inspection

History of Technology

5th Generation Technology

Precision engineered timber:

Precision engineered timber:Timber engineering knowledge and dedication of Japanese carpenters for over five generations.

1 Day Framing

Framing installation completed:

Framing installation completed:Within 1 day framing using crew of 10 people, special tools and rubber mallets.

Buy American

We employ skilled and trained workers:

We employ skilled and trained workers: Construction crews available to build your house quickly.

Milling Technology

Your timber is cut in a precision processing facility. Our 100 year legacy of joinery craftsmanship is now available in the USA . Our structures are milled in a few days, bundled and shipped to your building site. These structures are easily erected in 1 day, ready for roofing, external sheathing and windows.

Structures requiring weeks of cutting, framing and nailing lumber on site are no longer required. Precise joints are joined with rubber mallets and special wooden pins. Walls are anchored with durable anchor bolts and frames are held together with large 8” x 10” beams for increased rigidity and structural integrity. This same engineering is successful in Japan protecting structures from seismic events. Timber requirements are reduced and no waste piles of lumber on your building site. Computers calculate the timber cutting plan with approximately 4% lumber waste.